The Brief

Once we have received the brief from the client then we will have an internal meeting to discuss the best way forward and reply immediately stating that the brief has been received.

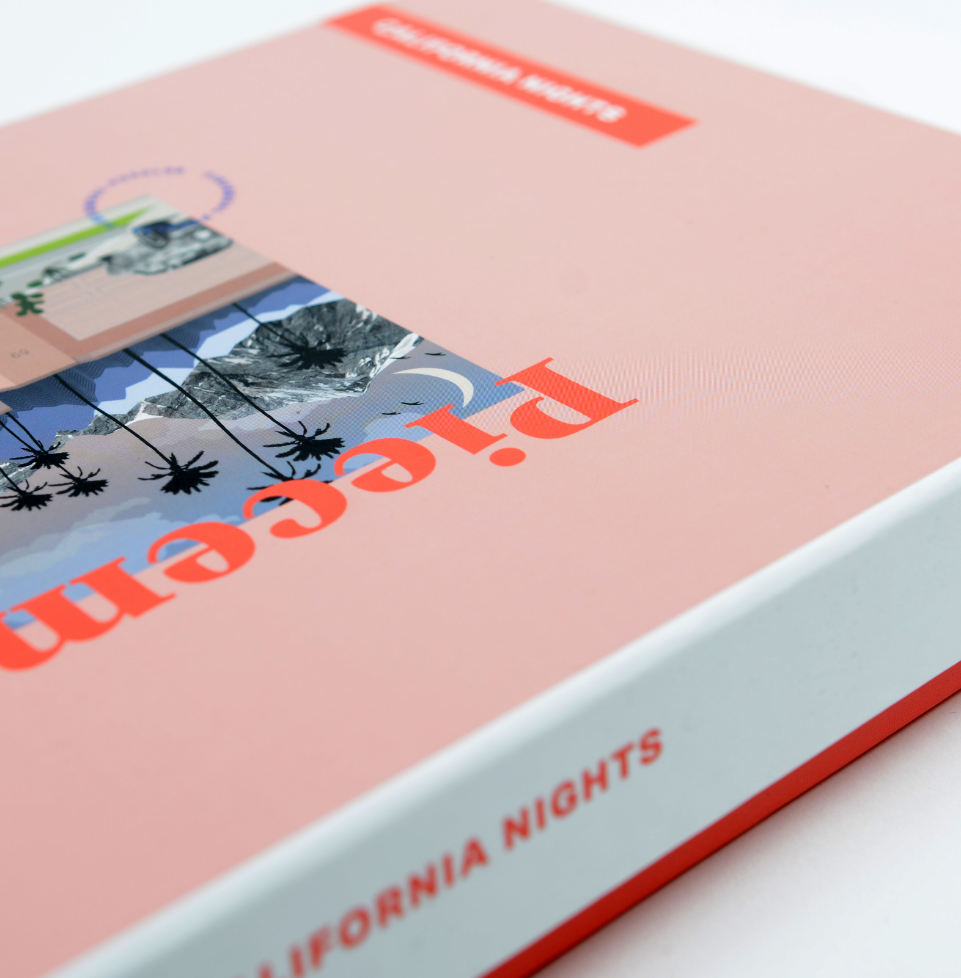

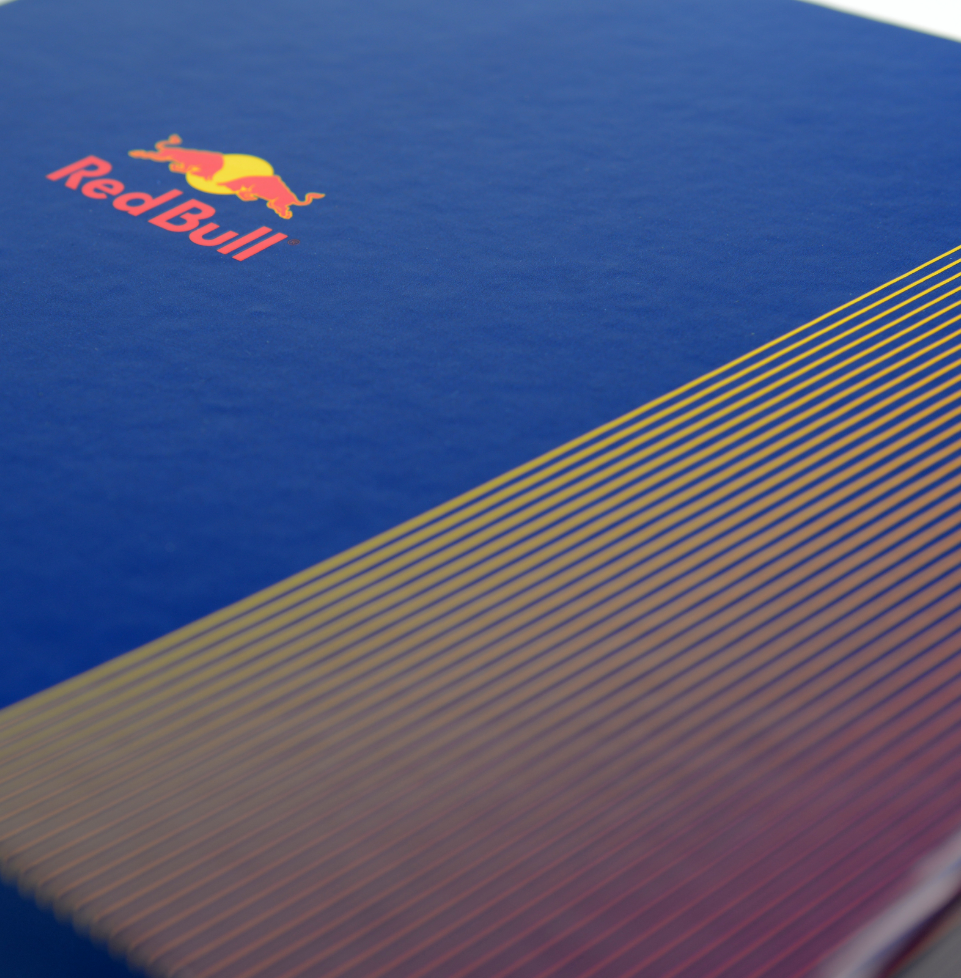

We want to make the ordering process as smooth as possible. We use a seven stage plan to get your packaging to you as soon as we can, at a cost that is within budget, and to the highest quality levels.

Once we have received the brief from the client then we will have an internal meeting to discuss the best way forward and reply immediately stating that the brief has been received.

During our initial design meetings we analyze the brief and decide on how best to produce the packaging. Using timeframe budget and final delivery time we then suggest the best way to create the sample prototypes.

Once we have design approval for the sample prototypes we tend to create between two to three samples showing different manufacturing processes. Once these are approved we then move to production sampling.

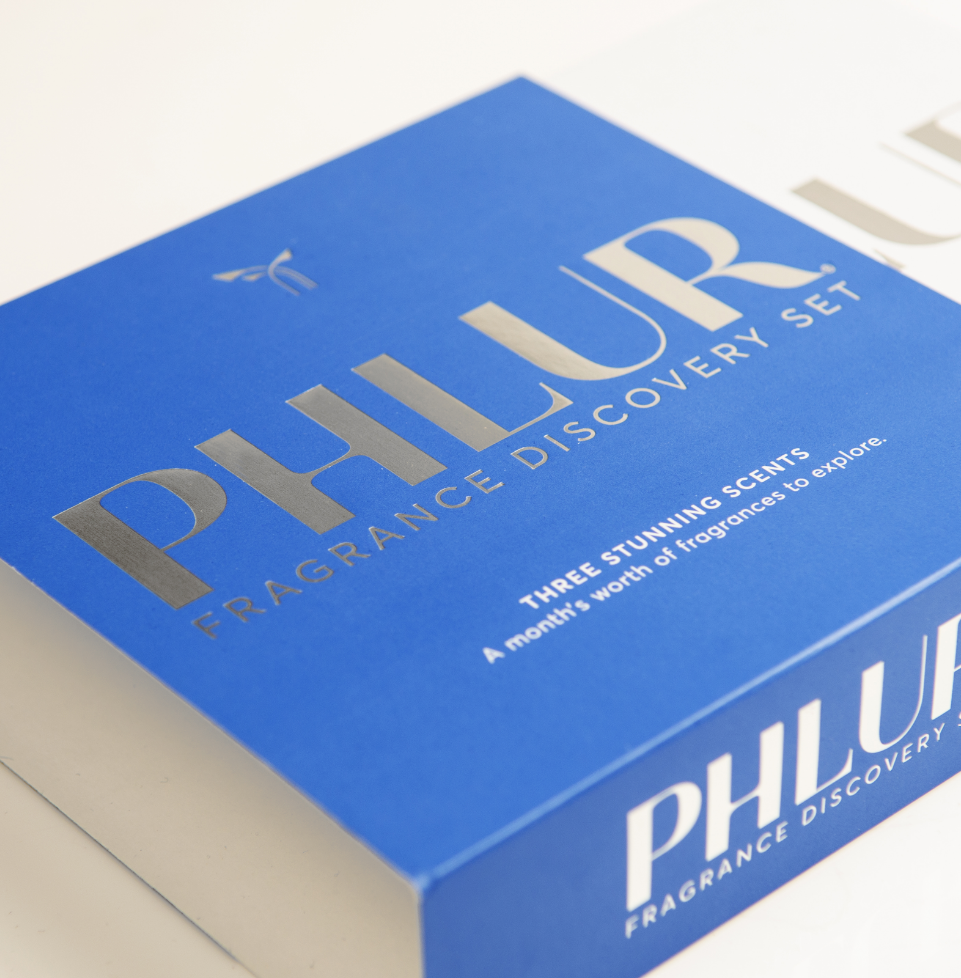

Once we have approval of the sample prototypes we then move to production approval where the client often attends press passes or quality control visits and signs of the production samples.

Once we have the final approval signed by the client the facility and Treadstone we move to production.

Once we have the approval we move to full production and packing. Each item is individually wrapped and placed inside a dust proof re-cycled bag and then placed inside a Kraft E-flute cardboard re-cycled box. These are then put into specifically designed shipping cartons to maximise the space on a pallet ready for shipping.

© 2024 Treadstone